- This is a pair of plastic sister flowers

- 发布日期:2018-5-7

There are two flowers in the plastic world. They are like snow clotted. It is a fluorinated polymer that is beautiful but not edible.

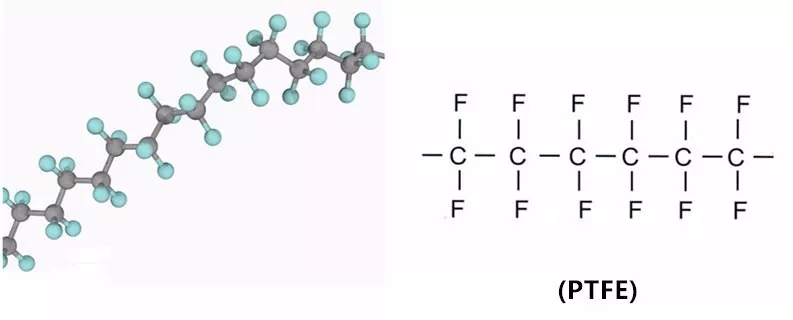

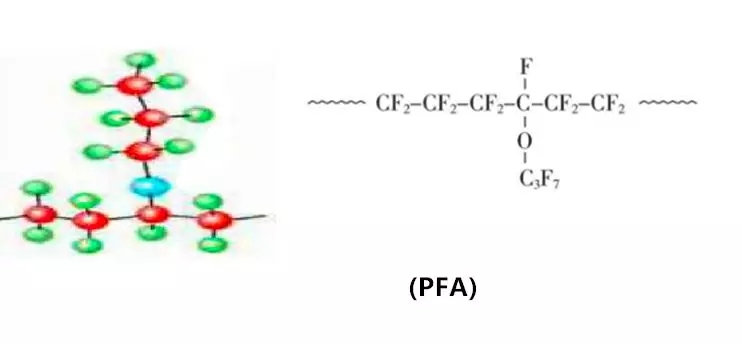

One: PTFE (polytetrafluoroethylene), high and low temperature resistance, chemical corrosion resistance, superior dielectric, very low friction coefficient, known as "the king of plastic". One: PFA (soluble polytetrafluoroethylene), its chemical properties are similar to that of PTFE. The difference is that PFA has good thermoplasticity and has the title of "the crown of fluorine plastic".

Why are there such similarities and differences?

This is to remove their structure. PTFE is mainly composed of C-F bond. Excellent chemical resistance is due to the strong binding force and stability of C-F bond.

When a C-F key in PTFE is replaced by C-O-C3F7 key, PFA is formed.

It can be seen that PFA is a fluorinated copolymer with PTFE as the substrate and perfluoroalkoxy group. Melting point viscosity has been improved to become a high performance thermoplastic material.

These two flowers, long and deep in love, they are dedicated to all kinds of anticorrosive components and lining materials, in general conditions can be replaced with each other, and called a pair of plastic plastic world sister flowers, PFA excellent thermoplastic, is the PTFE can not be compared. For example, GEKO is lined with ball valves.

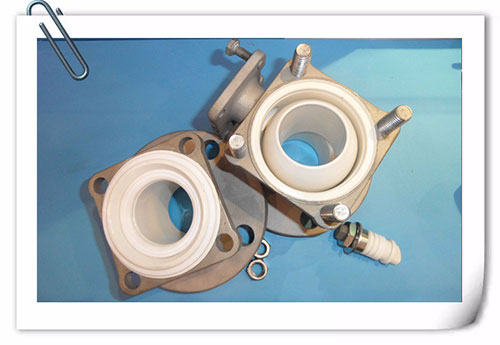

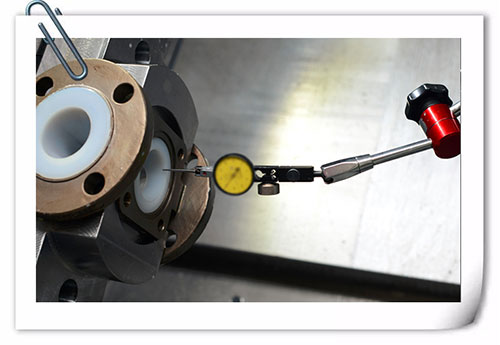

The valve body is lined with high quality PFA material with fluorine and lining, and PFA thermoplastic processing is lined in the valve body to ensure high sealing performance in the range of large pressure difference and large temperature difference. It is suitable for the transportation of liquid and gas medium in various industrial pipes, such as sulfuric acid, hydrofluoric acid, hydrochloric acid, nitric acid and other strong corrosive medium. The friction coefficient of PTFE is the lowest in the material and reaches the effect of self lubrication. As a general bushing material and sealing gasket, it is a popular choice. GEKO plug valves are routinely selected with three heavy PTFE seals.

The self lubricating and chemical corrosion resistant PTFE bushing perfectly encapsulated the whole cock surface, keeping the cover dry and without medium contact, so as to ensure the long and effective operation under bad conditions. GEKO cock valve always adheres to the "Highest Demands" concept, integrating high performance material, sophisticated advanced processing technology and strict and high standard quality guarantee system into every product, working closely with our customers, suppliers and so on. The technology is serving more partners. A proverb in Africa is a very accurate expression of our wishes: "if you want to move forward quickly, please walk independently; if you want to go further, please go together." If you have more technical questions about valve design, manufacture and after sale service, please contact the sales engineer of GEKO in Germany.

-

LAST:台湾盖科公司为Steinsvik提供优质的船用阀门

NEXT:德方代表到访中国分公司